6 Steps to Circular Procurement

Integrating circularity into your procurement process requires a significant policy shift, and an open mindset. Circular procurement starts with asking the right questions. Where you might once have focused mainly on price, lead times, and quality, you now also ask: Where does this product come from? Under what conditions was it produced? Is it designed for reuse?

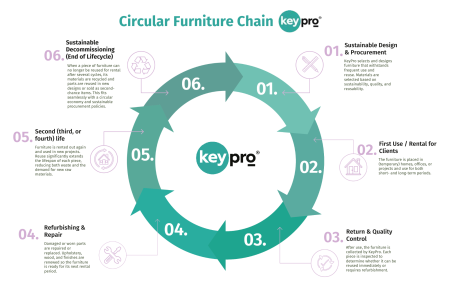

A circular procurement process consists of the following six steps:

1. Define Your Circular Procurement Vision

Start by formulating a clear vision of how procurement will contribute to your organisation’s sustainability goals. Do you want to reduce CO₂ emissions, save raw materials, or prevent waste? A clear vision creates direction and ensures stronger support across the organisation.

2. Analyse Current Procurement Streams

To make improvements, you first need insight into what you currently purchase. Which products have a short lifespan, create large amounts of waste, or are difficult, or even impossible, to recycle? These are the key focus areas for your circular procurement strategy. They also present quick wins, allowing you to learn and then expand your efforts further.

3. Choose the Right Suppliers

Circular procurement is a collaborative effort. Look for suppliers who offer circular products and services, and who truly prioritise circularity. Examples include renting circular furniture instead of buying, using recycled materials, or providing repair services. Be cautious of companies that use circularity only as a marketing term without real action.

4. Adjust Procurement Criteria

As mentioned, you’ll need to ask different questions when purchasing products. This also applies to the criteria you set for them. Require durability, the ability to dismantle and repair, use of secondary materials, and the presence of a material passport, for example.

5. Embed Circularity in Contracts

To safeguard circular procurement, make sure to record sustainability agreements in contracts. This could include agreements on product take-back after use, maintenance during the lifecycle, and the availability of spare parts. This ensures your commitments don’t fade over time and provides a solid framework for circular procurement.

6. Monitor and Evaluate

It’s essential to measure the results of your efforts. How much waste has been avoided? How much CO₂ has been saved? How many products have been reused? Measuring these outcomes enables accountability and helps shape future improvements. It also makes the results tangible for your whole organisation, increasing involvement and motivation.

A valuable tool for tracking circular efforts is an Environmental Aspects Register (MAR), a clear document or system where you record, monitor, and evaluate all environmental aspects of your activities. At KeyPro, we also use this tool to stay on course and make timely adjustments where needed.